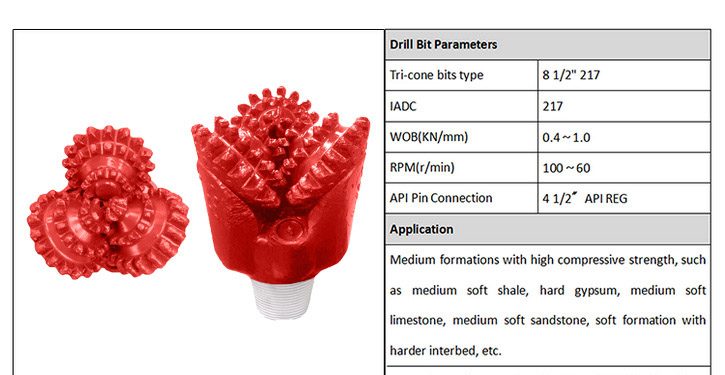

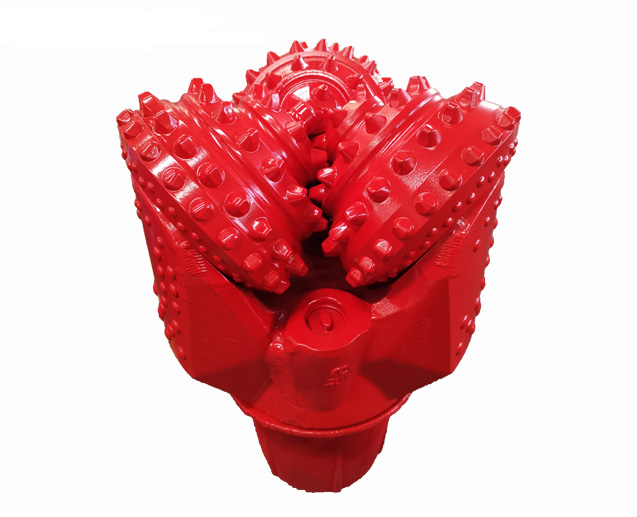

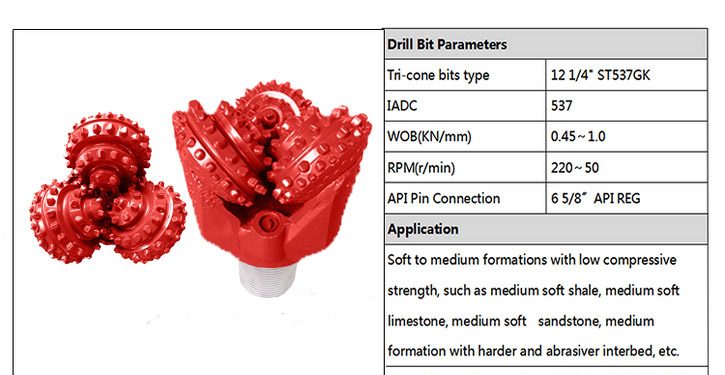

MILLED TOOTH BITS

features

Cutting Structure

High quality tungsten carbide steel teeth with wear/compact resistance.

Gauge Structure

Enhancedgauge protectionwithhardfacing on the shirttail, strengthenedleg with special insert tungsten carbide.

Bearing Structure

High precision rollingbearing,hardfacedbearing surfaceand bearing roller. Cone bearing inlaid with friction reducing alloy and then silver-plated,made the rotating more stability, safety and durability.

Option Features

Seal and Lubrication

The bearing seal is adapting the high quality HNBR O-ring. The better seal compression and the radial seal structure can enhance the seal performance. The compensation system and the high quality bit grease can limit pressure differential, and greatly increase the lubricating reliability.

Applications

Very soft formations with low compressive strength,such as shale/clay/ sand stone/soft limestone.etc.

We supply different size of this type of bit as clients’ requirement.